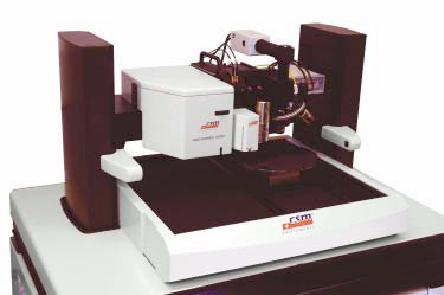

Nano-Micro Mechanical Tester

The device consists of four parts:

- Micro Indenter – Scratch

- Nano Indenter

- Atomic Force Microscope

- Optical Microscope

Indentation (Nano/Micro)

The Indentation device is used to determine the mechanical properties (Hardness, Elastic Modulus) of different materials (soft, hard, brittle and flexible) and thin films formed from these materials.

By using a suitable indenter, a load is applied up to a determined maximum value perpendicular to the sample surface, and after this maximum load value is reached, a gradual restoration is performed again. The mechanical properties of the sample are determined by analyzing the LOAD (N) - DEPTH (nm) curves obtained as a result of loading and restoring.

Specifications

Micro Indenter

- Load range: 0.03 – 20 N

- Maximum Depth: 180 μm

- Indenter: Vickers

Nano Indenter

- Load range: 0.1 mN – 400 mN

- Maximum Depth: 100 μm

- Indenter: Berkovich

Scratch Tester

The scratch tester is used to determine the mechanical properties of thin films and coatings, such as fracture, deformation and adhesion. It is also used to characterize the friction and adhesion force of the substrate and film system.

This technique relies on creating a controlled scratch in the material with a sharp tip. The tip material (usually diamond or hard metal (WC)) is scratched on the coating surface with a constant or increasing load. At the critical load value, the coating starts to break. The critical loading value is determined precisely by the sound sensor (MST & RST ) attached to the loading arm.

At the same time, refractions are observed with an optical microscope. Critical loading information is used to determine the adhesion properties of different film-backing combinations. With the scratch device, the application force, friction force and depth of advancement are determined during the test, and these parameters are evaluated together with the sound information and the mechanical properties of the coating are determined.

Scratch Tester Features (Micro)

- Loading range: 30 mN - 25 N

- Maximum friction force: 25 N

- Maximum Scratch length: 12 mm

- Scratch speed: 0.4 to 500 mm/min

- Maximum depth: 1mm

Applications

Hardness and Elastic modulus measurements of different types of materials (semiconductors, glasses, ceramics, composites and biomaterials).

Determination of the mechanical properties of thin films and coatings such as fracture, deformation and adhesion.

Sample Requirements

All specimens must be flat and polished.

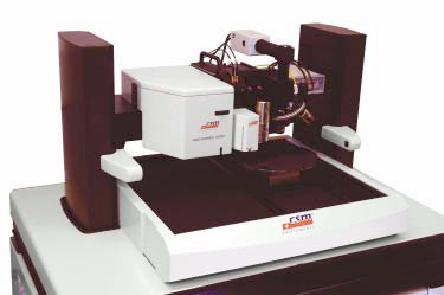

The device consists of four parts:

- Micro Indenter – Scratch

- Nano Indenter

- Atomic Force Microscope

- Optical Microscope

Indentation (Nano/Micro)

The Indentation device is used to determine the mechanical properties (Hardness, Elastic Modulus) of different materials (soft, hard, brittle and flexible) and thin films formed from these materials.

By using a suitable indenter, a load is applied up to a determined maximum value perpendicular to the sample surface, and after this maximum load value is reached, a gradual restoration is performed again. The mechanical properties of the sample are determined by analyzing the LOAD (N) - DEPTH (nm) curves obtained as a result of loading and restoring.

Specifications

Micro Indenter

- Load range: 0.03 – 20 N

- Maximum Depth: 180 μm

- Indenter: Vickers

Nano Indenter

- Load range: 0.1 mN – 400 mN

- Maximum Depth: 100 μm

- Indenter: Berkovich

Scratch Tester

The scratch tester is used to determine the mechanical properties of thin films and coatings, such as fracture, deformation and adhesion. It is also used to characterize the friction and adhesion force of the substrate and film system.

This technique relies on creating a controlled scratch in the material with a sharp tip. The tip material (usually diamond or hard metal (WC)) is scratched on the coating surface with a constant or increasing load. At the critical load value, the coating starts to break. The critical loading value is determined precisely by the sound sensor (MST & RST ) attached to the loading arm.

At the same time, refractions are observed with an optical microscope. Critical loading information is used to determine the adhesion properties of different film-backing combinations. With the scratch device, the application force, friction force and depth of advancement are determined during the test, and these parameters are evaluated together with the sound information and the mechanical properties of the coating are determined.

Scratch Tester Features (Micro)

- Loading range: 30 mN - 25 N

- Maximum friction force: 25 N

- Maximum Scratch length: 12 mm

- Scratch speed: 0.4 to 500 mm/min

- Maximum depth: 1mm

Applications

Hardness and Elastic modulus measurements of different types of materials (semiconductors, glasses, ceramics, composites and biomaterials).

Determination of the mechanical properties of thin films and coatings such as fracture, deformation and adhesion.

Sample Requirements

All specimens must be flat and polished.