Universal Testers

Instrument: Zwick (250 kN) ve Instron Model 3367 (30 kN)

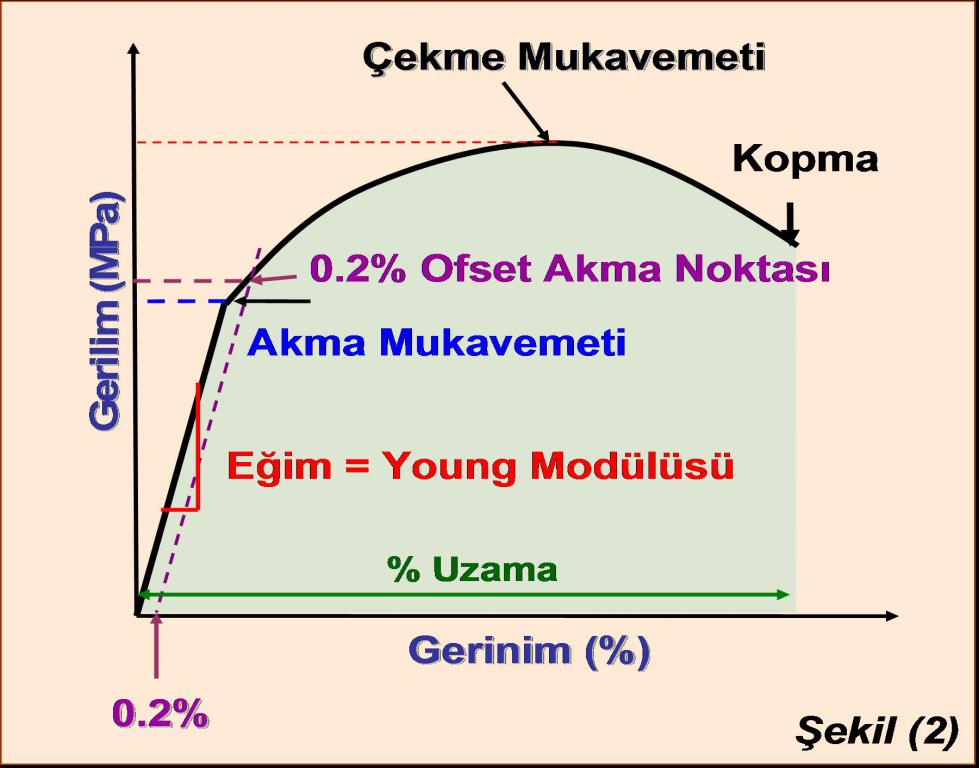

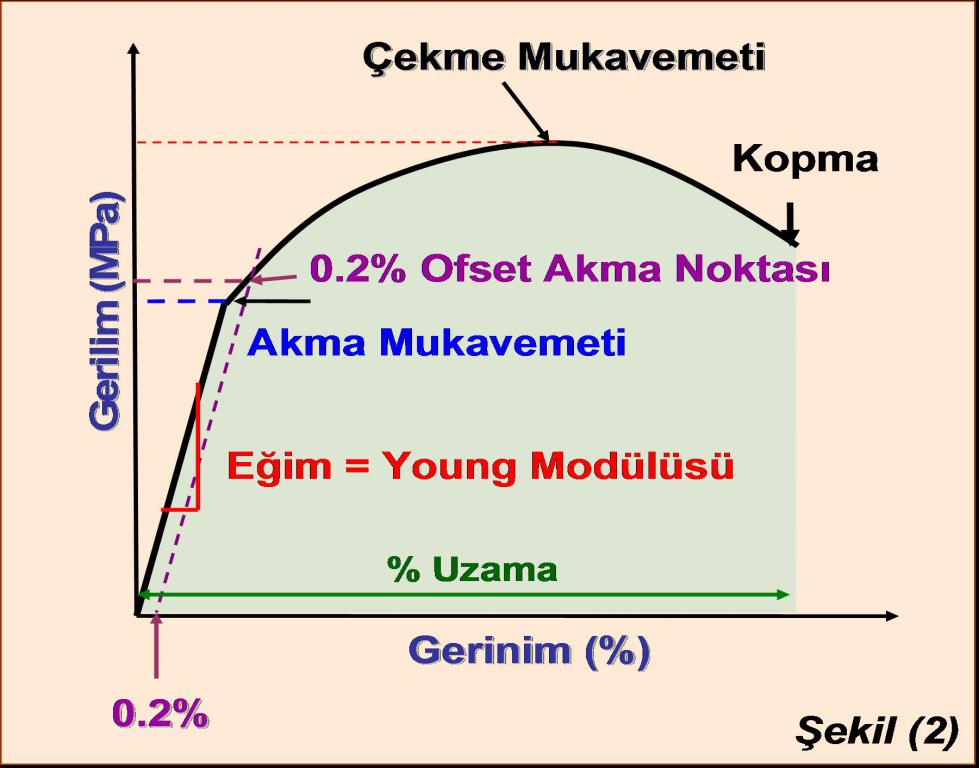

The tensile test is the most common test method used to determine the mechanical properties of materials. In the tensile test, the strength of a material against a static and slowly applied load is measured. A suitable tensile test specimen (Figure (1)) is placed in the universal testing machine and a force (load) is applied to the specimen. In the tensile test, the amount of elongation in the material is measured using an extensometer, the applied force (load) is measured using a load cell, and a stress-strain curve (Figure (2)) is obtained by using these measured elongation and load values. With the tensile test, the ductility, strength, and stiffness of the materials can be determined.

In addition to the tensile test, it is also possible to perform compression and bending tests in the universal testing device.

Specifications

Universal Testers:

|

Specification |

Zwick |

Instron |

|

load Capacity |

250 kN |

30 kN |

|

Additional Load Cells |

100 N, 10 kN |

1 kN

|

|

Extensometer |

Adjustable Gauge |

25 mm Gauge Length |

|

Test |

Pull, Compress, 3-4 point bend |

Tensile, Compression, High Temperature Tensile (1000 °C ) |

Sample Requirements

Test pieces should be prepared in accordance with the standards.

Instrument: Zwick (250 kN) ve Instron Model 3367 (30 kN)

The tensile test is the most common test method used to determine the mechanical properties of materials. In the tensile test, the strength of a material against a static and slowly applied load is measured. A suitable tensile test specimen (Figure (1)) is placed in the universal testing machine and a force (load) is applied to the specimen. In the tensile test, the amount of elongation in the material is measured using an extensometer, the applied force (load) is measured using a load cell, and a stress-strain curve (Figure (2)) is obtained by using these measured elongation and load values. With the tensile test, the ductility, strength, and stiffness of the materials can be determined.

In addition to the tensile test, it is also possible to perform compression and bending tests in the universal testing device.

Specifications

Universal Testers:

|

Specification |

Zwick |

Instron |

|

load Capacity |

250 kN |

30 kN |

|

Additional Load Cells |

100 N, 10 kN |

1 kN

|

|

Extensometer |

Adjustable Gauge |

25 mm Gauge Length |

|

Test |

Pull, Compress, 3-4 point bend |

Tensile, Compression, High Temperature Tensile (1000 °C ) |

Sample Requirements

Test pieces should be prepared in accordance with the standards.